For many manufacturers, production times, error rates, maintenance costs and supply chain disruption weigh on operating efficiency. These problems can often make it harder for them to compete with more efficient rivals and meet customer needs. But AI-integrated manufacturing processes are starting to transform manufacturing for the better.

Integrating Artificial Intelligence (AI) into manufacturing processes can lead to faster growth and innovation. According to McKinsey, AI has made work across industries more productive and efficient by 20%. And it's grown in popularity to such an extent that 77% of manufacturers have already implemented AI solutions. Further, in 2025, the AI manufacturing solutions market is projected to reach $8 billion in revenue.

For manufacturers, AI helps in real-time analytics and decision-making by processing vast amounts of data from sensors and machines instantly. This allows for immediate adjustments in production processes, improving efficiency, reducing waste, and improving overall quality.

In this blog, you’ll learn how AI is reshaping the manufacturing industry, its impact on workforces, its benefits to manufacturing, how it improves quality checks and more.

Let’s dive in.

Real-world examples of AI in manufacturing

AI in manufacturing has contributed to a large-scale advancement in manufacturing, automation and data analysis. This can be felt across various industries like automotive, pharmaceuticals and even aerospace manufacturing.

Automotive industry

AI tracks and predicts failures through AI’s predictive analytics. It also advances quality control through computer vision systems that can detect defects in real-time.

For example, Tesla uses AI in its factories to watch and improve the work of its assembly lines. Tesla’s AI-powered cameras and sensors find problems right away, making sure that every vehicle is safe.

Aerospace and defence

AI assists in the design and engineering of complex systems, such as aircraft and spacecraft, by analysing large datasets. It also helps with planned maintenance to make sure equipment is reliable and safe.

For example, Boeing gathers plenty of data from their aircraft, which includes information about engine performance, environmental factors and other flight data. Maintenance staff may proactively solve problems by using AI algorithms to analyse this data and find trends and anomalies. Further, Boeing uses this data to make its planes better by validating new designs with the help of AI, according to the required demand and safety standards.

Consumer goods

AI helps in forecasting demand by analysing consumer behaviour and market trends.

For example, Procter & Gamble (P&G) uses AI to forecast demand for its products by analysing consumer behaviour and market trends and helps adjust production levels to meet demand.

Pharmaceuticals

AI accelerates drug discovery by analysing vast amounts of data to identify potential compounds and evaluate the workings of medicine.

For example, Pfizer uses AI in its medicine discovery to analyse large datasets and identify potential new medications. AI algorithms also help in assessing the efficacy and safety of compounds, accelerating medicine’s development.

Electronics

AI-driven robotics and automation systems improve the speed and precision of assembly lines. Also, computer vision systems are used to find defects and make the product of optimal quality.

For example, Foxconn, a major electronics manufacturer, uses AI-driven robotics to automate assembly lines, increasing production speed and precision. Foxconn’s plans to build and scale "AI factories" that can process vast amounts of data will support digitalised manufacturing and new business lines.

Impact on workforce and employment

AI has now influenced how we live and work. Reports suggest that in the coming years, AI will complement or replace 40% of jobs across the world.

Industries today are trying to create a balance between AI automation and human labour. So, let's dig in deeper to understand the impact of AI on job roles within the manufacturing industries.

1 - Improved efficiency and productivity

AI can automate repetitive and mundane tasks, allowing humans to focus on more creative and value-added activities. For example, AI-driven robots can handle assembly line tasks with speed, reducing production time and increasing output.

2 - Improved quality control

AI systems can watch production processes in real-time and find problems that humans might have missed. Machine Learning algorithms can analyse data from sensors and cameras to identify patterns and check for quality.

3 - Predictive maintenance

AI can tell when machinery is likely to break by looking at data from sensor cameras and past maintenance records. This predictive maintenance approach allows manufacturers to schedule repairs and reduce unexpected breakdowns, saving costs and extending the lifespan of the equipment.

4 - Optimised supply chain management

AI can optimise supply chain operations by forecasting demand, managing inventory and handling logistics. Machine Learning can analyse market trends, customer behaviour and historical data to provide accurate demand forecasts. This helps manufacturers better plan their production schedules and reduce waste.

5 - Improved worker safety

AI can significantly improve worker safety by identifying and mitigating potential hazards. For example, AI-powered systems can monitor factory environments for unsafe conditions, such as high noise levels or hazardous material leaks.

AI powered factories can also assist in training workers to prepare them for such situations.

AI and Quality Control

AI-enabled Quality Controls (QC) integrated into the manufacturing line have proven transformative. For example, including computer vision can help in monitoring the products in the manufacturing unit.

Real-time monitoring and inspection

AI systems with advanced sensors and cameras can watch production lines in real-time. They can detect defects, inconsistencies overlooked by humans. This continuous monitoring checks quality issues and addresses them immediately, reducing the likelihood of defective products reaching the market.

Automated testing and validation

AI can automate the testing and validation processes for products to meet the required standards. They can perform tests ranging from functional and performance testing to safety and compliance checks.

Data-driven decision making

AI can process and analyse vast amounts of data from various sources, providing insights that can inform decision-making. For example, AI can help identify the root causes of quality issues, enabling manufacturers to implement targeted improvements for overall product quality.

Upgraded traceability and compliance

AI can make it easier to track products by tracking the whole process from start to finish. This is particularly important in industries with strict regulatory requirements, such as pharmaceuticals and aerospace. This will reduce the chance of not following these rules and the penalties they come with.

Conclusion: embracing AI in manufacturing

AI improves manufacturing through predictive maintenance, quality control, supply chain optimisation and demand forecasting. This leads to increased efficiency, reduced costs and improved product quality.

Embracing AI and other emerging technologies can drive innovation, boost competitiveness and create new opportunities for growth in the manufacturing sector.

This is where working with the best in the industry significantly increases your chances of successfully building a high-quality app, powered with AI.

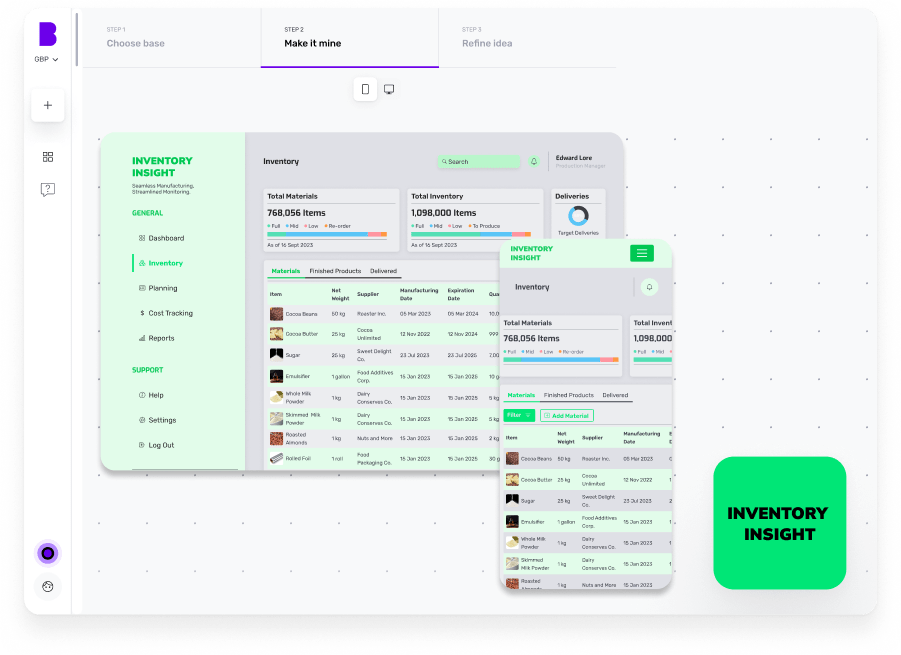

Builder.ai helps you build your app efficiently. We:

✅ - Assign you a dedicated project manager, who keeps all stakeholders on your app project aligned and on track — you never need to speak to a software developer or write a single line of code

✅ - Speed up development time by giving you access to a comprehensive library of reusable features, fitted together by AI

✅ - Give you upfront costs and competitive timelines so your project stays under control

If that’s something you’d like to explore, please get in touch 👇

Create robust custom software today

100s of businesses trust us to help them scale.

Book a demoBy proceeding you agree to Builder.ai’s privacy policy

and terms and conditions

FAQs

How's AI used in manufacturing?

AI in manufacturing optimises production through predictive maintenance, quality control and supply chain management. It upgrades efficiency, reduces costs and improves product quality by analysing data and automating processes.

What are some common applications of AI in manufacturing?

AI in manufacturing is commonly used for predictive maintenance, quality control, supply chain optimisation and process automation. It helps reduce downtime, improve efficiency and improve product quality.

How does AI improve efficiency in manufacturing?

AI improves manufacturing efficiency by projecting equipment failures, optimising production schedules, reducing waste and automating routine tasks, leading to faster throughput and lower costs.

What challenges does the manufacturing industry face with AI adoption?

Manufacturing faces AI adoption challenges such as high costs, data quality issues, skill gaps, integration with legacy systems, resistance to change, regulatory compliance, security concerns, scalability and proving ROI.

Can you provide examples of generative AI in manufacturing?

Generative AI in manufacturing includes designing complex parts, optimising production processes and creating predictive maintenance schedules. It can be used to generate 3D models for additive manufacturing and optimising supply chain logistics.

What role does AI play in semiconductor manufacturing?

AI in semiconductor manufacturing optimises production processes, enhances defect detection and improves yield rates. It also aids in predictive maintenance, supply chain management and energy efficiency, ensuring higher quality and cost-effectiveness.

Harsh Priya is a writer at Builder.ai. She has over 3 years of experience in content marketing, spanning across fields like AI, Machine Learning, software, tech, health and lifestyle. With a background in English literature and a fervent passion for research and analysis, Harsh transforms complex concepts into compelling and insightful narratives that educate and drive significant reader engagement.

Facebook

Facebook X

X LinkedIn

LinkedIn YouTube

YouTube Instagram

Instagram RSS

RSS